SAJ-type anti-fall safety device is widely used gear rack and fork lift gear cone-shaped progressive anti-fall safety device, it is a limit to the construction of the lift cage or heavy protection target speeding down to effectively prevent and eliminate the cage Or the equivalent of the target fall accident occurred in the ideal security device. I produced the anti-fall safety device has a reasonable structure, well-made, stable performance, reliable quality brake smooth, low noise and other characteristics, by the majority of manufacturers customers pro-Lai.

Fall test and post-action recovery anti-fall safety device after the new installation, must be rated load drop test. In the official put into operation after the use of at least every three months to do a rated load drop test. Falling test steps:

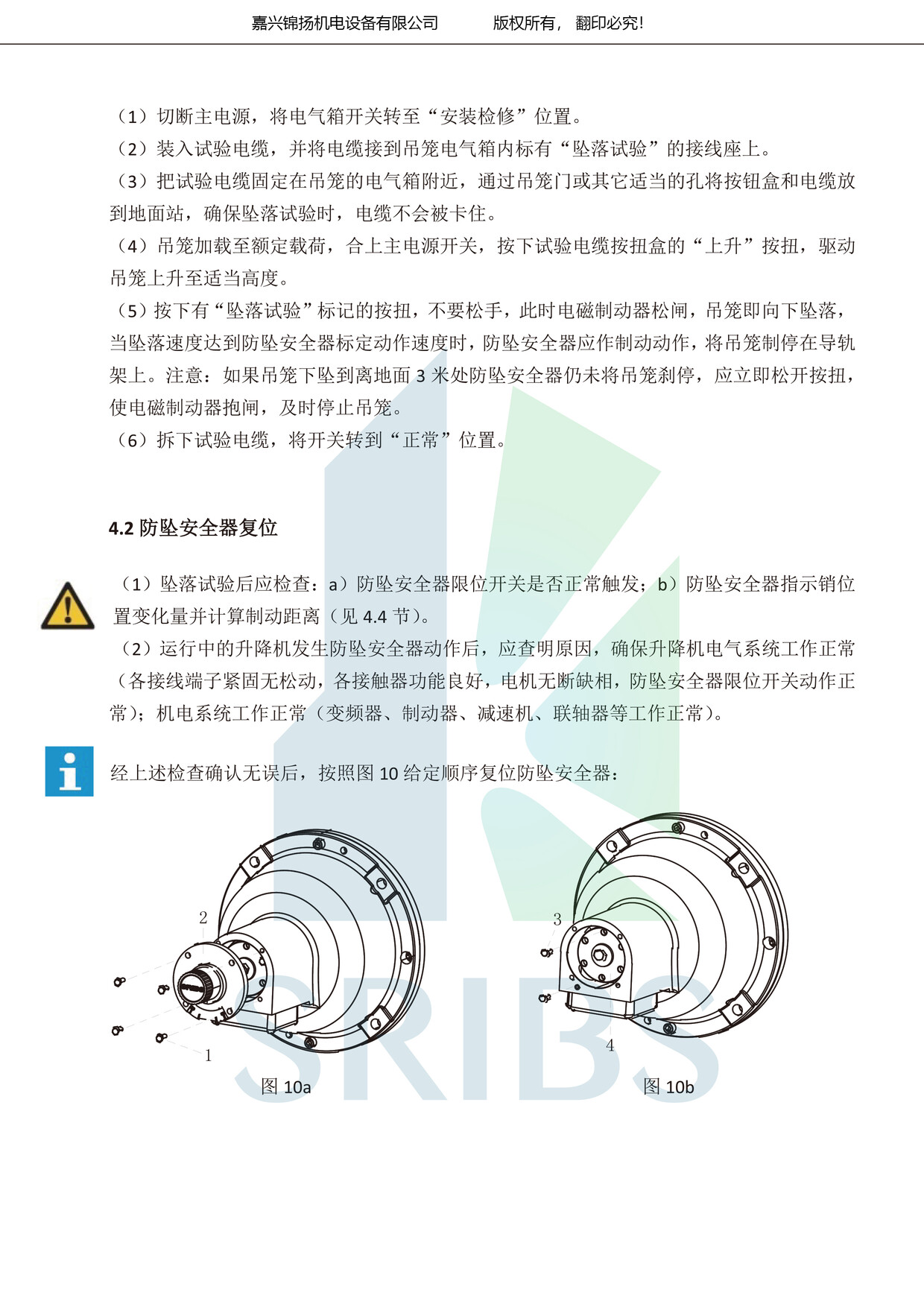

(1) Turn off the main power supply and turn the electrical box switch to the “install and repair” position.

(2) Install the test cable and place the cable drop in the cable box with the “drop test” terminal block.

(3) Fix the test cable near the electrical box of the cage and place the press and the cable into the ground station through the door or other suitable hole. To ensure that the drop test, the cable will not be stuck.

(4) the cage is loaded to the rated load, close the main switch, press the test cable button on the box “up” button, drive the cage rose to 10 meters from the ground height.

(5) press the “fall test” mark button, do not let go, this time the electromagnetic brake loose, hanging down the cage, when the fall speed reaches the anti-fall safety device calibration speed, anti-fall safety device immediately action, Stopped the cage on the rail shelf. (Note: if the cage down to 3 meters from the ground at the anti-fall safety device has not stopped the cage, this time should immediately release the button in order to use the electromagnetic brake brake. Timely stop the cage, to prevent the cage bottom.

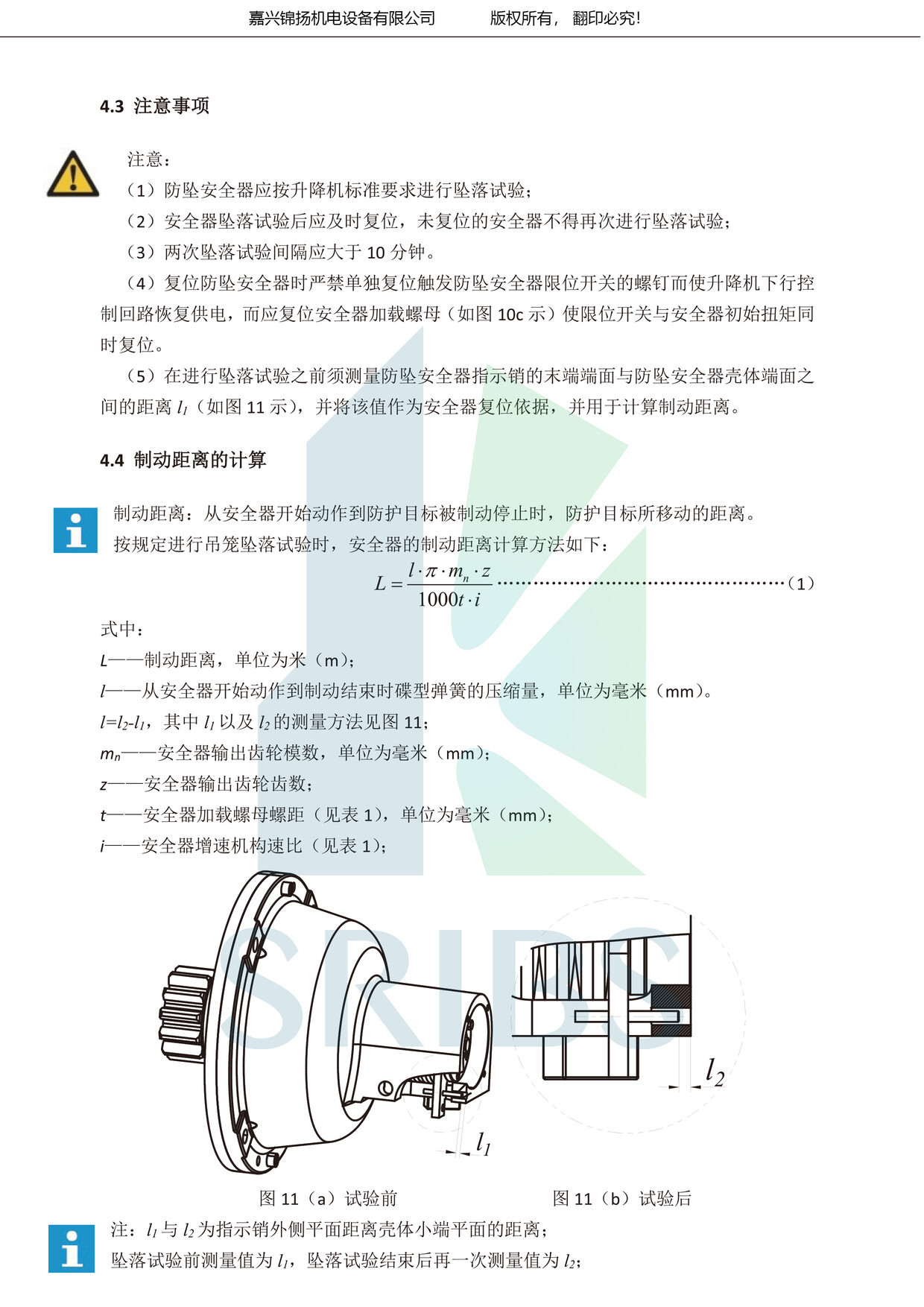

(6) Normally, the braking distance of the cage should be 0.3-1.2 m (excluding the distance at which the cage is free to descend) from the start of the safety device to the suspension. The braking distance is calculated by the following method: S = L · π · m · Z / 2 where: S: braking distance mm L: indicating pin end displacement mm m: gear modulus m = 8Z: gear Number of teeth z = 15

We guaranee our product all origional GJJ high quality item, no fake item supply.